All filter plates are linked together for rapid open and close. All filter cloths can be washed simultaneously.

LASTA MC is a FULLY automatic horizontal filter press, which has been designed for relatively easy to discharge filter cakes as with mineral applications. Fast cycle time, efficient performances are provided for Mineral Concentrate and Tailings application.

FEATURES

ISHIGAKI LASTA-MC Presses are used in the mining industry.

Where large throughput and “Low Moisture Content” dewatering is required.

The ISHIGAKI LASTA-MC Press is a Fully Automatic filter press with many unique features.

Fully automatic operation

High production capacity

Large capacity is available

Robust and simple design

Technical feature:

Quality: Certified ISO9001 and ISO14001 Approved

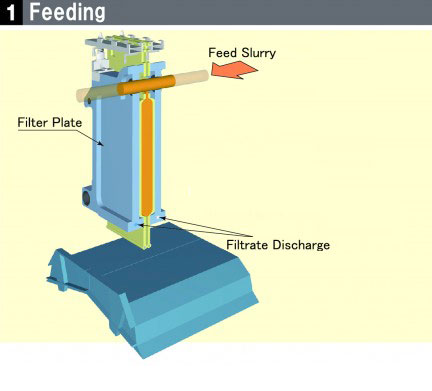

1. Feeding

The slurry is fed via the feed port at the top of the filter plate. The solids in the feed build up as dry cake while the filtrate exits through the filtrate ports.

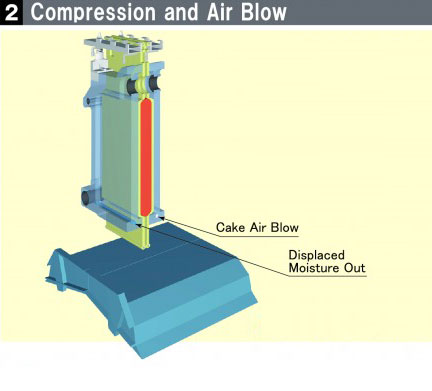

2. Compression and Air Blow

Air is fed from one side for the chamber, displacing cake moisture and exits through the next chamber

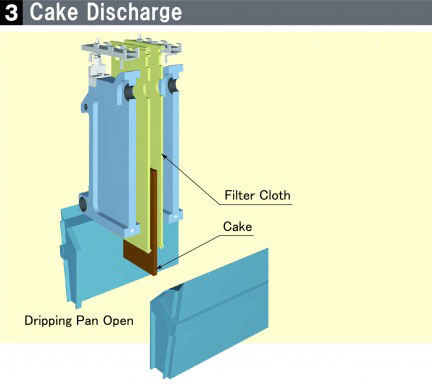

3. Cake Discharge

When all the filter plates are opened, the cake discharges by gravity. If not, a detection systems is activated and assists the cake discharge

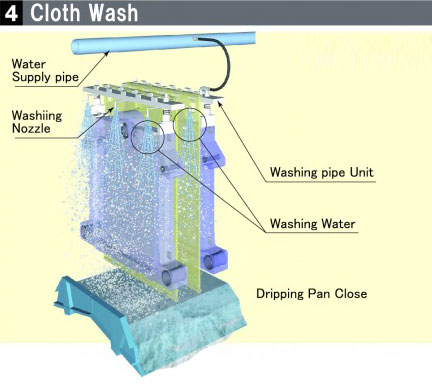

4. Cloth Wash

Upon completion of the cake discharge process, the filter cloth is washed from the top of the plate pack.

Efficient filter cloth wash system

one of the key factors to high press availability and low cloth maintenance lies in the ability to wash the filter cloth efficiently. With the cake doors closed and the press open, the stationary shower bars are actuated, washing the exposed cloths. The wash water flows down the face of the cloths efficiently cleaning. The shower bars and nozzles are positioned above the chamber to eliminate the potential of clogging from filter.

Cloth Support assembly

The cloths, which are hung from support bars at the top of each plate, can be readily and individually changed by one person in a few minutes, requiring no skills or tools. The support bars are located by springs which are designed to compress under cake load. No adjustments are required during cloth installation.

Discharge monitory system and back-up mechanism

if abnormalities in the operating process arise result in incomplete cake discharge after press opening, a photo-electric beam will detect its presence and a back-up discharge mechanism will be automatically activated, two vibration rails running the full length of the press are mounted to lifting cylinders. Upon activating the mechanism, the rails are raised coming into contact with the lowered cloth support assembly and its attached cake.

A vibration force is transmitted to dislodge the filter cake.

After a pre-set time, the vibrators are turned off and the rails return to their “down” position.

Compression Pressure (Diaphragm)

| MODEL | PRESSURE |

| L | 0.7 MPa |

| H | 1.5 MPa |

| R | 2.0 MPa |

| S | 2.9 MPa |

Cake wash system

Wash water passes through the filter cake, foreign substances in cake are removed or precious substances in case are extracted.

Normal cake wash: Wash water is fed into each chamber from the top feeding port, passing through the cake and discharged via the filtrate port.

Back cake wash: The wash water is fed from filtrate port of one plate, it passes through the cake and then discharged from the filtrate port of the next plate.

Material option

Standards LASTAs

Frame: mild steel and stainless steel

Filter plate: PP

Diaphragm: rubber

Other materials are available to suit customers’ requests.